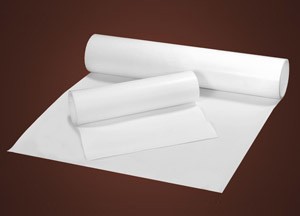

PTFE SHEET

PTFE SHEET

STAR POLYMER are manufacturing products as per requirements from the customers. Our wide products range to PTFE and Filled Grade PTFE products Molded Sheets. STAR POLYMER PRODUCTS intends to distinct from routine products range in Indian Market to manufacture:

Standard Size : Thickness From 0.05 mm to 5 mm SKIVED Sheet & PTFE Sheet Thickness from 5 mm to 100 mm.

1000 mm x 1000 mm and thickness from 5 mm to 100 mm

1200 mm x 1200 mm and thickness from 5 mm to 100 mm

1500 mm x 1500 mm and thickness from 5 mm to 20 mm

All non standard sizes available as per customer specifications.

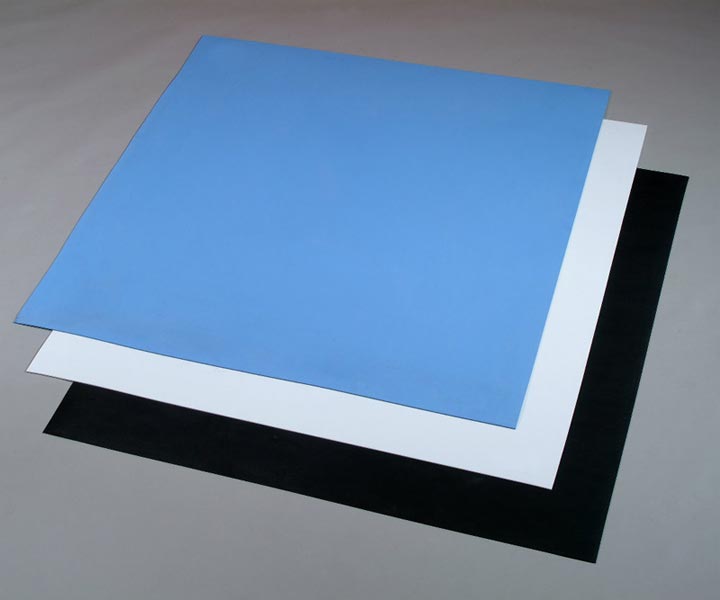

Available Grades :

» Virgin PTFE

» 15% Peek PTFE

» 15 To 25% Glass Filled PTFE

» 25 To 35% Carbon Filled PTFE

» Special Grade as per customer specification

- 1200 X 1200 MM PTFE MOULDED SHEET (1.2 Mtr X 1.2 Mtr)

- PTFE MOULDING UP TO MAX DIA 1500 MM (1.5 Mtr)

CONSTRUCTION OF MATERIALS

- THE PROPERTIES OF PTFE

- Temperature limitation

| Maximum continuous service Temperature: | 260º C |

| Melt Point: | 327º C |

- Chemical inertness

- Coefficient of friction

| Static Coefficients of friction: | 0.10 |

| Kinetic coefficient of friction : | 0.05 |

- Specific gravity ASTM D792 14 – 2.2

- Tensile Strength ASTM D638 280 – 350kg/cm2

- Non – Stick

| Surface tension | 18.5 dyne/cm |

| Contact angle water | 104º – 111º |

| Hexadecane | 37º – 45º |

- Elongation ASTM D638 100 – 300%

- Water absorptioin ASTM D570 <0.01%